"CleverUsername" (CleverUsername)

"CleverUsername" (CleverUsername)

08/31/2015 at 10:31 ē Filed to: None

17

17

100

100

"CleverUsername" (CleverUsername)

"CleverUsername" (CleverUsername)

08/31/2015 at 10:31 ē Filed to: None |  17 17

|  100 100 |

If you havenít already removed or installed a transmission, thereís only one thing you need to know: it sucks. Theyíre big, dirty, and heavy, and they require a certain amount of precision to install. Hereís how to make the job slightly less painful.

DISCLAIMER: Donít hurt yourself. If you hurt yourself, blame yourself.

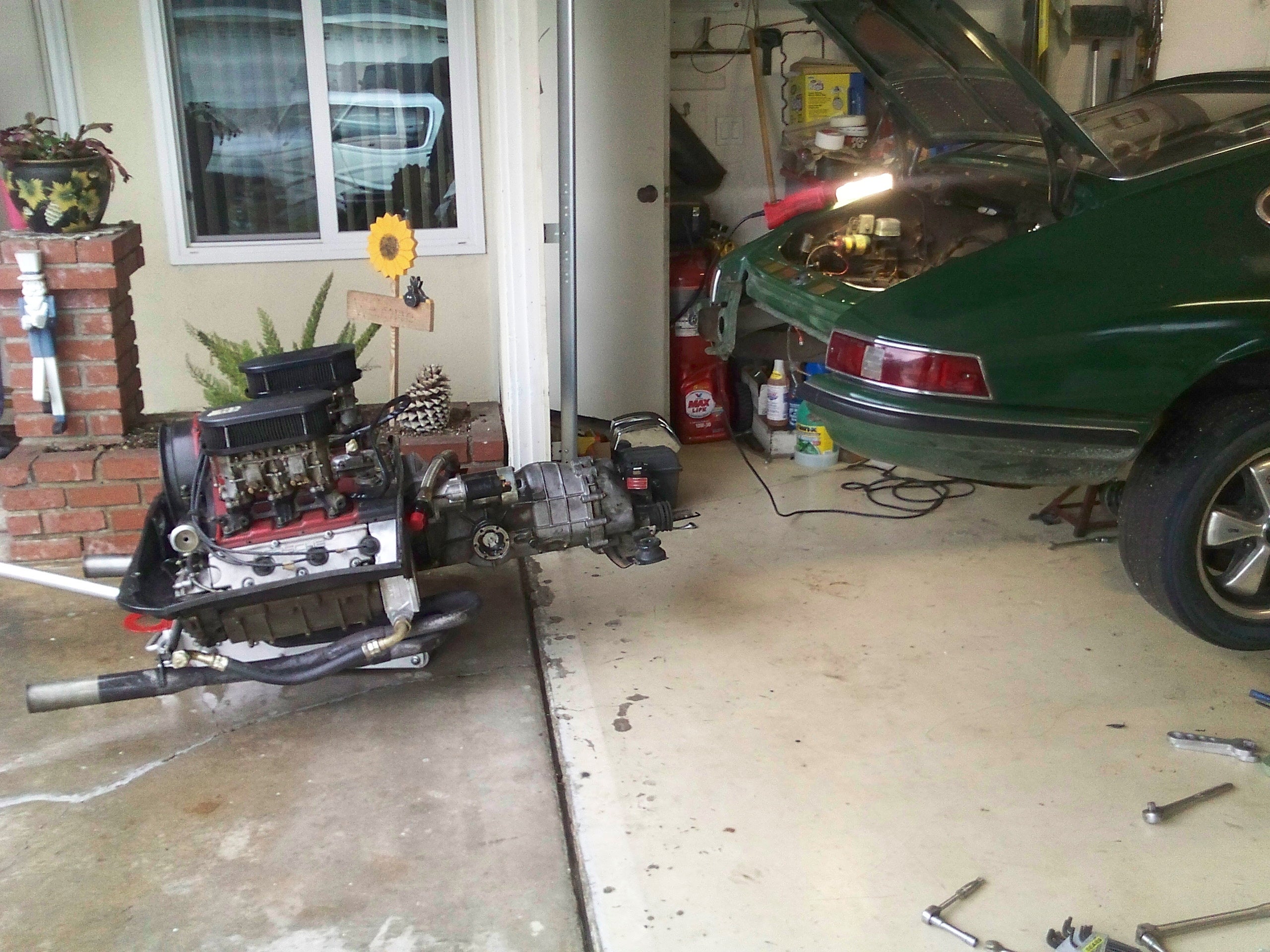

The job of installing a transmission is daunting because they are awkwardly placed in the center of the underside of your car (weíll get to FWD complications later). Itís also really heavy and it needs to be lifted up, then pushed forward to mate with the engine. Generally, the transmission needs to be aligned perfectly with the crankshaft in the engine to slip together. This is all very difficult when youíre on your back, lifting a 150 lb chunk of greasy metal a few feet into the air, with almost no room on the sides.

Professional shops generally have two things that you donít: a lift and a transmission jack. A lift allows the installer to raise the car in the air, so that the mechanic doesnít have to lay on the floor, in a puddle of transmission fluid. A transmission jack is a special jack foró wait for itó transmissions. It is specially adjustable to articulate the transmission into whatever yoga pose is required to get it to mate with the engine, all without the need for the mechanic to deadlift the weight of a college freshman. Another bonus of transmission jacks is that they let you lift an automatic transmission without damaging the pan on the underside.

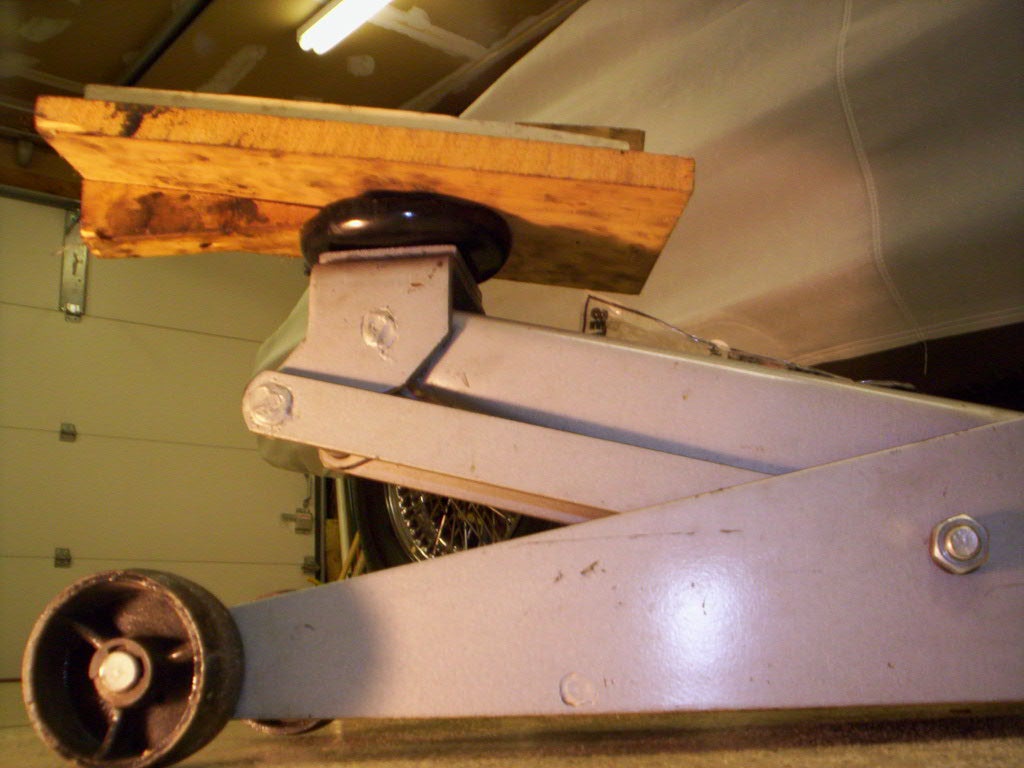

Of course, you donít have one of these. Nor do you have a lift. What do you have? You have a floorjack and an engine hoist. If you donít have an engine hoist (or engine crane. Whatever. ), you can rent one relatively cheaply. Generally, the cost to rent one for a weekend isnít much less than the cost to buy, especially used. You can probably find both an engine hoist and a floor jack for less than $300, with a little Craigslist-Fu. Youíll also need a !!!error: Indecipherable SUB-paragraph formatting!!!

So, armed with your tools, get the car on jack stands and move the hoist over the rear of the engine. Route the ratchet strap around the front of the transmission and up to the hoist arm. Support the rear of the transmission with your floor jack. You can now lift the transmission from both ends carefully and without the risk of a hernia.

There you go. You can lift your transmission carefully into place without fear of it crushing you.

Of course, youíre going to have to modify your method for a FWD transmission, as well as for however your car is set up. For what itís worth, manual transmissions are usually lighter. In my case, I now have a perfectly functional, leak-free commuter car that wonít be a pain to drive in daily traffic.

yamahog

> CleverUsername

yamahog

> CleverUsername

08/31/2015 at 10:39 |

|

ďall without the need for the mechanic to deadlift the weight of a college freshman.Ē

Bruh, do u even lift

/s, thx for the writeup

Santiago of Escuderia Boricua

> yamahog

Santiago of Escuderia Boricua

> yamahog

08/31/2015 at 10:42 |

|

We need to save this for future reference

Meatcoma

> CleverUsername

Meatcoma

> CleverUsername

08/31/2015 at 10:45 |

|

You forgot to mention where you had to remove the hood for this as well.

If I was just replacing a transmission I probably wouldnít remove the hood.

RamblinRover Luxury-Yacht

> CleverUsername

RamblinRover Luxury-Yacht

> CleverUsername

08/31/2015 at 10:46 |

|

This is a really good tip. I *usually* have access to a lift, but you never know. My project is capable of dropping the powertrain whole out the bottom, but thatís not that common these days.

MikaelVroom

> CleverUsername

MikaelVroom

> CleverUsername

08/31/2015 at 10:48 |

|

When I pulled the T5 out of the V6 Mustang in the junkyard, I put an old backseat and a tire beneath it and just yanked it backwards. It landed gently on the tire and that was that.

Now itís installed in the M3 and I have to pull it out to check on the clutch this afternoon, not sure how thatís going to work. I may try your method.

McMike

> CleverUsername

McMike

> CleverUsername

08/31/2015 at 10:49 |

|

Last time I changed a transmission, I made my own.

Mrs McMike pumped it while I laid underneath it, holding it with my knees while I tried to get the upper bolts in.

She had the jack in one hand, and a phone in the other with ď9 - 1Ē dialed.

Iíve been smarter.

Margin Of Error

> CleverUsername

Margin Of Error

> CleverUsername

08/31/2015 at 10:49 |

|

So what if you are working on a Porsche 944 and the tranny is between the rear wheels ?

TurboS60

> CleverUsername

TurboS60

> CleverUsername

08/31/2015 at 10:50 |

|

I helped a buddy change the transmisson on his Thunderchicken with the car just up on ramps(front and rear). Wasnt too bad till trying to get transmission out from under the car, but finally did and when I picked it up I realized my friend didnt drain it first as all the fluid poured out of the dipstick hole and down the front of me.

litespud

> CleverUsername

litespud

> CleverUsername

08/31/2015 at 10:51 |

|

Fine and dandy - alas, the TR6 tranny is removed upwards through the passenger compartment - requiring prior removal of the seats, the dash support (the bit that holds the radio) and the transmission tunnel. On the plus side, at 60-70 pounds, itís likely the smallest transmission youíre ever likely to encounter. My son and I installed one this weekend (no jacks or lifts required), and weíre still speaking to each other (barely).

yamahog

> Santiago of Escuderia Boricua

yamahog

> Santiago of Escuderia Boricua

08/31/2015 at 10:52 |

|

Itís a better plan than ďok who has the highest benchĒ

Voice of C. Montgomery Burns

> McMike

Voice of C. Montgomery Burns

> McMike

08/31/2015 at 10:52 |

|

Not sure what youíre driving but those wheels look nice, probably could have afforded something safer. ;)

Mr. MiniBig, where's my coffee?

> Meatcoma

Mr. MiniBig, where's my coffee?

> Meatcoma

08/31/2015 at 10:53 |

|

Itís a BMW, the hood hinges from the front so I donít think he needed to remove the hood.

theshinobi01

> CleverUsername

theshinobi01

> CleverUsername

08/31/2015 at 10:53 |

|

DISCLAIMER: Donít hurt yourself. If you hurt yourself, blame yourself.

Best advise ever!

DrifterSteve

> McMike

DrifterSteve

> McMike

08/31/2015 at 10:53 |

|

When i changed the transmission on my 240sx, i used a jack just like you show. I got it as close as i could and then bench pressed it the rest of the way in.

thejustache

> Meatcoma

thejustache

> Meatcoma

08/31/2015 at 10:54 |

|

To be fair, in the case of this example it looks like itís a BMW with a forwards opening hood and he probably didnít need to think about it

Scott

> CleverUsername

Scott

> CleverUsername

08/31/2015 at 10:54 |

|

Damn where was this article 3 months ago when I was paying the mechanic 2grand to replace the transmission in my truck. Ohh well he also stored it all winter since tow trucks in the Northeast are apparently in capable of driving in the snow unless it is a life or death emergency, and delivering a truck up a plowed driveway does not qualify. Also he did a warranty replacement of the fuel pump which I would have had him do anyway.

lawlence

> Meatcoma

lawlence

> Meatcoma

08/31/2015 at 10:56 |

|

Nope, thatís an E30 with a front hinged hood. The solution is to buy an E30.

Gary Yogurt

> CleverUsername

Gary Yogurt

> CleverUsername

08/31/2015 at 10:57 |

|

This reminds me of all the 325e bits Iíve got laying around.

SMRZ

> McMike

SMRZ

> McMike

08/31/2015 at 11:01 |

|

Ah, the things love and a good life insurance policy will make us do to help our partners!

Drakkon- Most Glorious and Upright Person of Genius

> CleverUsername

Drakkon- Most Glorious and Upright Person of Genius

> CleverUsername

08/31/2015 at 11:02 |

|

Ratchet straps will save our whole civilization someday.

Fragile_this_side_up

> Voice of C. Montgomery Burns

Fragile_this_side_up

> Voice of C. Montgomery Burns

08/31/2015 at 11:02 |

|

That really doesnít look all that unsafe.. Iíve pulled miata transmissions with just a jack... No ďfancyĒ adapter.. never had an issue. Just work slow and smart.

Fragile_this_side_up

> MikaelVroom

Fragile_this_side_up

> MikaelVroom

08/31/2015 at 11:03 |

|

Rip the back seat out of the M3 and let Ďer drop!! :)

Urambo Tauro

> CleverUsername

Urambo Tauro

> CleverUsername

08/31/2015 at 11:04 |

|

When I rebuilt my transmission, I recruited the help of a friend who had made his own hydraulic hoist. Itís not as hillbilly as you might think.

He had two fork-lift mast assemblies, complete with chains & lift cylinders, and securely mounted them about 9-10 feet apart on the concrete floor of his pole barn. A hydraulic pump, driven by a few spare 12V batteries, operates the masts, and can do so independently, if a slight tilt was desired for draining fluids.

Both masts have beefy stops every couple of inches to rest on. Each mast has two telescoping swing arms, which could be positioned wherever the ideal lift points are on the car.

This set up has saved him so much money, he bought a transmission jack.

Urambo Tauro

> CleverUsername

Urambo Tauro

> CleverUsername

08/31/2015 at 11:05 |

|

Nothing to be a-frayed of.

crowmolly

> yamahog

crowmolly

> yamahog

08/31/2015 at 11:07 |

|

Itís a floor press, yo

And all you need is some of this

crowmolly

> CleverUsername

crowmolly

> CleverUsername

08/31/2015 at 11:09 |

|

FWIW if you have an equipment rental place nearby itís worth a phone call. You can rent something like this for 24 hours. The ď3DĒ adjustment can be worth the price alone.

Nonster

> CleverUsername

Nonster

> CleverUsername

08/31/2015 at 11:12 |

|

When I was in high school I swapped in a Borg Warner T-18 transmission into my Jeep CJ-7.

Thats not the exact pic, but its pretty much the same. The transmission weighs about 150 lbs and the transfer case bolted to it weighs around 50 lbs. Me and a buddy just balanced it on a floor jack and man-handled it into place. The bottom is round so that didnít make things any easier.... I never want to do that again

anonkc

> CleverUsername

anonkc

> CleverUsername

08/31/2015 at 11:14 |

|

Clever approach. Iíve used homemade stuff like some of the other posts. But I grew up and plunked down a few coins for a transmission jack . Raises and lowers with a 1/2Ē drive ratchet. Can be had for less than retail $99 with a harbor freight 20% coupon found in their flyers, mailers etc.

sklooner

> CleverUsername

sklooner

> CleverUsername

08/31/2015 at 11:14 |

|

For RWD I have always used the Ďsupport bell housing with feet, tailshaft with crotch, crawl on back into position and somehow lift. -do not try with Mercedes Ponton boxes- they have a big spike on the bottom that will disembowel you. On a happier note the Volvo M56 manual actually has a lifting lug on the top

jamisparker

> Margin Of Error

jamisparker

> Margin Of Error

08/31/2015 at 11:15 |

|

Just use a floor jack, itís not as long so you just balance it as best you can.

GoesLikeHell

> CleverUsername

GoesLikeHell

> CleverUsername

08/31/2015 at 11:20 |

|

Looks like the leg of the engine hoist is going to be in the way when trying to get under it to bolt it up.

One reason I hate automatics besides the driving experience is that they are so much heavier. Hurt my back lifting one off the tailgate of my truck while simultaneously soaking my right leg in smelly burnt fluid. Iíve changed a few, usually with a board balanced on a floor jack to lift them in. When I was younger and into older Mopars I would just roll underneath on a creeper with the trans on my chest and muscle them in, but that was old 3spd and 4spd boxes that werenít that heavy. Now I work mostly on fwd and Iíve got a lift so things gotten easier.

Kaufmania: Mark Webber's Stunt Double

> CleverUsername

Kaufmania: Mark Webber's Stunt Double

> CleverUsername

08/31/2015 at 11:20 |

|

This is the exact arrangement we rigged last year for an engine/transmission swap in an old Chevy 1500. Great minds think alike.

Sam

> CleverUsername

Sam

> CleverUsername

08/31/2015 at 11:20 |

|

As usual, the answer is Miata. The 5 speed weighs like 50 pounds. We literally picked it up and just put it on the engine.

TheRealBicycleBuck

> CleverUsername

TheRealBicycleBuck

> CleverUsername

08/31/2015 at 11:22 |

|

When my uncle and I replaced the clutch on my momís civic wagon, my uncle was the transmission jack. The car was up on stands and he was on a creeper underneath. He bench-pressed the transmission into place. I was too scrawny to do much more than put in the bolts.

I gained a new respect for him that day.

Equana

> CleverUsername

Equana

> CleverUsername

08/31/2015 at 11:22 |

|

What do you need that crap for?? Method 1) Put tranny on floor jack, pump up, wrestle into position to engage clutch shaft, install bolts. or 2) Call friend, both of you just muscle it into place from each side (what are you a weakling??), one holds, one installs bolts.

Method one works in a paved place. Method 2 works in a grassy paddock at the race track and if you know WTF you are doing, takes 40 minutes max in a RWD race car. Plenty of time between practice and qualifying to swap trans and eat lunch.

hyperventilatingwookiee

> CleverUsername

hyperventilatingwookiee

> CleverUsername

08/31/2015 at 11:23 |

|

apparently, nobody here have ever heard of

Britt

> CleverUsername

Britt

> CleverUsername

08/31/2015 at 11:24 |

|

the last time I helped a buddy put in a transmission (Ford c4) my chest was the ďtransmission jackĒ and we discovered that the rear seal on the tranny was bad due to the burnt tranny fluid pouring onto my crotch. Fun times.

Threw those pants away.

( me, on my back, under car, on jack stands resting on BIG blocks of wood, tranny on my chest, wiggling it into position while he sat on the firewall, windshield out of car, and tried lining up bolts/input shaft... I do not recommend, but it can be done and wouldn't take as long as you think... but will suck a little and you will want a beer afterwards.)

Santiago of Escuderia Boricua

> crowmolly

Santiago of Escuderia Boricua

> crowmolly

08/31/2015 at 11:26 |

|

We do not need meth to lift a transmission

crowmolly

> Santiago of Escuderia Boricua

crowmolly

> Santiago of Escuderia Boricua

08/31/2015 at 11:28 |

|

Pfft. Who wants to live to 40 anyways?

Chairman Kaga

> CleverUsername

Chairman Kaga

> CleverUsername

08/31/2015 at 11:28 |

|

What if you have a transaxle, though?

PunJabber

> CleverUsername

PunJabber

> CleverUsername

08/31/2015 at 11:30 |

|

Or just do yourself a favor and call this guy.

El-Verde

> Voice of C. Montgomery Burns

El-Verde

> Voice of C. Montgomery Burns

08/31/2015 at 11:30 |

|

At first glance I thought E39...

Now, looking closer they look like wire wheels from something british...MGA?

nitroram33

> CleverUsername

nitroram33

> CleverUsername

08/31/2015 at 11:31 |

|

So I guess Iím cheating on this one. Almost have my new shop finished and in it lives a new Bendpak 10k pound two post lift that I need to finish up the install on today and I just ordered a transmission jack on Friday...

Brearly

> CleverUsername

Brearly

> CleverUsername

08/31/2015 at 11:33 |

|

Now try it with an NP205 transfercase attached to the back of the transmission in a truck running 37ís..

DirtTrackRacer13

> CleverUsername

DirtTrackRacer13

> CleverUsername

08/31/2015 at 11:34 |

|

Great tip! I have also found that 2 ratchet straps hanging from your shop rafters work great as a makeshift motorcycle lift. I have saved thousands over the years by simply removing and reinstalling my own wheels for tire and bearing replacements.

Prophet of hoon

> CleverUsername

Prophet of hoon

> CleverUsername

08/31/2015 at 11:36 |

|

#somepeopleskidsthese days. Back when I was a kid (meaning, there were no laws against beating your child OR forcing them to put a transmission in) we didnít have ratchet straps and would get tasked with balancing the transmission on the jack while dad jacked up the transmission. If the kid lost a finger, he was not allowed to whine until after the transmission was in AND the dad was no longer nearby.

it is so nice to know that as time progress people get smarter. I like the use of ratchet straps - good idea!

defenestrae

> CleverUsername

defenestrae

> CleverUsername

08/31/2015 at 11:36 |

|

See, youíre talking about the *right* way to do it. Or, you can be like me, drop the entire passenger side suspension, unbolt the motor mounts and slowly pull the thing out like a water buffalo breech-birthing a cactus without Anastasia.

Frankly, Iíve only ever had a few tranny swaps (what we used to call it before Caitlin Jenner got so brave) that were easy, and those are usually on older cars where you could smuggle locomotive parts in the extra space you had under the hood.

Excellent article, btw. More like this, please.

Cixelsyd

> CleverUsername

Cixelsyd

> CleverUsername

08/31/2015 at 11:37 |

|

We did this in college when we replaced the clutch on my 1980 Toyota Corolla. Our tool was a bench press bar with a small chain looped around the front of the transmission and then routed up through the spot where the gearshift was before we removed it. (Back wasnít removed, as we just needed access to the clutch, not the entire transmission) We didnít use an engine hoist. Just a dude on each side of the car lifting the bar while a brave/stupid soul crawled under and bolted everything in place. Worked like a charm!

golfball

> CleverUsername

golfball

> CleverUsername

08/31/2015 at 11:37 |

|

Neat, but this may be a situation where a cheap Harbor Freight tool is the answer. You can get a transmission jack for $80 with the standard 20% off coupon. It will be the right tool for the job and it doesn't matter that it's Harbor Freight quality when you only are using it a few times.

lucky8ballcars

> McMike

lucky8ballcars

> McMike

08/31/2015 at 11:39 |

|

the fact that you have photos of your creative idiocy earns you triple Kinja points. Well done Mrs McMike for sticking with him.

TheChafing

> RamblinRover Luxury-Yacht

TheChafing

> RamblinRover Luxury-Yacht

08/31/2015 at 11:40 |

|

Isnít dropping out the bottom how most modern engines come out of the chassis?

On my 2005 BMW, it appears that almost the entire contents of the engine bay could be lowered out the bottom after disconnecting the drive shaft and subframe bolts.

Vox Calamitous in Deserto

> El-Verde

Vox Calamitous in Deserto

> El-Verde

08/31/2015 at 11:44 |

|

Cantilever hood. E34 or E30.

RamblinRover Luxury-Yacht

> TheChafing

RamblinRover Luxury-Yacht

> TheChafing

08/31/2015 at 11:45 |

|

If theyíve got a subframe, sure. You raise a good point that I hadnít really thought of. However, thatís also ďdropping the subframeĒ, which is often more involved than just dropping the engine and trans, which was mostly a Mopar thing. Granted, a subframe drop gives you a drivetrain served on a platter. I guess I think of cars from the 90s as being modern too often.

thejohnfist

> CleverUsername

thejohnfist

> CleverUsername

08/31/2015 at 11:46 |

|

I had to change out the trans in my 1984 Camaro... not once, not TWICE, but THRICE! The worst part was trying to hold that damn thing and make VERY minute adjustments to get the case bolt holes to line up with the engine bolt holes. Then of course you needed a 2-3ft ratchet extension to tighten any of them. Ugh. Also, had to change it so many times because the rebuilder fudged it twice over.

Anticyclone

> CleverUsername

Anticyclone

> CleverUsername

08/31/2015 at 11:46 |

|

When I was 16, I installed a 700r4 in a 4wd Blazer. I asked my more knowledgeable friend how were were going to do it. ďWell, weíll just put it on my chest and scooch under there...Ē Somehow it worked.

Achieve

> CleverUsername

Achieve

> CleverUsername

08/31/2015 at 11:50 |

|

Guess my system of laying on my back. lowering it to my chest, then sliding out from under it didnít make the Top 5 list.

Reverse for installation.

CheesePatrol

> CleverUsername

CheesePatrol

> CleverUsername

08/31/2015 at 11:51 |

|

Wow this method looks ungainly. A transmission scissor jack is easier to use and can probably be found on Craigslist for cheap or possibly for rent locally. Harbor Freight sells this model for $100. Its cheaper, easier to store than an engine hoist, and thereís no need to use another jack.

Jim is one of KFCs secret ingredients

> CleverUsername

Jim is one of KFCs secret ingredients

> CleverUsername

08/31/2015 at 11:51 |

|

I enjoyed deadlifting a transfer case into my jeep, but the transmission would really suck.

michael bleggi

> CleverUsername

michael bleggi

> CleverUsername

08/31/2015 at 11:55 |

|

i used a longboard! on my bmw! a few weeks ago lol. i coulde used this

protodad

> CleverUsername

protodad

> CleverUsername

08/31/2015 at 11:56 |

|

Had to do this recently. It was FWD and the transmission is lighter than most wheels these days however.

StupidIceberg

> CleverUsername

StupidIceberg

> CleverUsername

08/31/2015 at 12:00 |

|

My friend Ryan has perfected his ďpelvic thrustĒ method with old Toyotas. You rest the trans on your pelvis and stomach, then thrust to lift it into place, leaving your hands free to bolt it in.

fdawg4l

> McMike

fdawg4l

> McMike

08/31/2015 at 12:01 |

|

This. You win the Mr. McMike.

fdawg4l

> TheChafing

fdawg4l

> TheChafing

08/31/2015 at 12:08 |

|

And steering knuckle, brake lines, fuel lines, radiator lines, oil cooler lines, harness, and subframe. Ask me how I know. Trust me, on my 08 German luxobarge, the trans alone is way easier than the whole drivetrain including motor. If youíre limber, have a lift, and have some well placed mirrors, you can drop the trans by yourself in 4 or 5hrs. (More like 10 to 15 for me because Iím slow and paranoid.)

rayJoyal

> crowmolly

rayJoyal

> crowmolly

08/31/2015 at 12:08 |

|

I had to buy one to finish doing the clutch on my TA.

Done plenty of automatic trans R&Rís and you just use a floor jack and muscle it in place, but I needed to be exact to get the trans input shaft to slide in at just the right angle or no amount of force would get it in.

My 2 cents: If youíre enough of a car guy to be changing a transmission, youíll likely be doing it a second time so buy the jack. Harborfreight sells them for $150. Sell it on craigslist for $75 after if you donít think youíll do it again.

crowmolly

> rayJoyal

crowmolly

> rayJoyal

08/31/2015 at 12:09 |

|

T56 I presume?

Brickman

> CleverUsername

Brickman

> CleverUsername

08/31/2015 at 12:09 |

|

Nice. I used a riding mower jack and a support made of scrap wood :D

El-Verde

> Vox Calamitous in Deserto

El-Verde

> Vox Calamitous in Deserto

08/31/2015 at 12:10 |

|

Weíre talking about McMike, not the main article.

I donít know how youíd see a cantilever hood when the car has a cover on it.

SawdustTX

> CleverUsername

SawdustTX

> CleverUsername

08/31/2015 at 12:13 |

|

Last one I changed was a Toyota Corolla 4-spd manual. Lifted the car about 12Ē on jack stands, then used a floor jack, skateboard, and an assortment of lumber cutoffs. It actually went quite well, but I havenít tackled anything bigger since then....

Shane Broussard

> CleverUsername

Shane Broussard

> CleverUsername

08/31/2015 at 12:13 |

|

Go to Harbor Freight, spend $100 on one of these:

Easy.

moetop

> El-Verde

moetop

> El-Verde

08/31/2015 at 12:14 |

|

ďMrs McMike pumped it while I laid underneath it, holding it with my kneesĒ

What are we talking about again??

R Henry

> CleverUsername

R Henry

> CleverUsername

08/31/2015 at 12:14 |

|

Uhm...this is what just about every knuckle-dragging redneck has been doing since about 1927, but without the cherry picker, often without even a floor jack. I have done this countless times. óThe very light weight manual transmission in my old Pinto could be thrown up to the back of the engine with one hand and a shoulder, leaving the other hand to install the bellhousing bolts. Really heavy automatics, like the iron case Ford FMX, might need the added persuasion offered by a floor jack if I am shagged out. Real men, not the kind who are rendered impotent without their smart phone, can do this easily.

fdawg4l

> MikaelVroom

fdawg4l

> MikaelVroom

08/31/2015 at 12:20 |

|

Are the trans and bell housings identical?! I never would have guessed!

...unless...unless you did the unthinkable and did a 5.0 swap on an M car. In which case you're simultaneously my hero and dead to me.

Mopar4life

> CleverUsername

Mopar4life

> CleverUsername

08/31/2015 at 12:28 |

|

I prefer sliding under the car, trans on my chest, give it the lift and wiggle into place, and there ya go, trans installed.

El-Verde

> moetop

El-Verde

> moetop

08/31/2015 at 12:32 |

|

She had the jack in one hand,

Yeah youíre right I have no idea.

NoahthePorscheGuy

> CleverUsername

NoahthePorscheGuy

> CleverUsername

08/31/2015 at 12:34 |

|

To swap in a 356 transmission, all you need is some jackstands and a floor jack with a piece of wood in it. You donít need no stinking engine hoist. Just a buddy and alot of swearing.

TheChafing

> fdawg4l

TheChafing

> fdawg4l

08/31/2015 at 12:36 |

|

Kinda depends on why youíre doing this. Iíd be inclined to agree that most of time, itís better to bite the bullet and pull just the trans. I can imagine circumstances where it would make sense to just pull the whole shebang, though. For instance, changing the cam chain tensioners on one of those horrific backwards mounted VW V8s or W12s.

CleverUsername

> TheChafing

CleverUsername

> TheChafing

08/31/2015 at 12:36 |

|

Iíve done this before on my 1600. Itís actually a ton easier on some cars, and itís really easy if you were removing the engine as well anyway.

CleverUsername

> Urambo Tauro

CleverUsername

> Urambo Tauro

08/31/2015 at 12:39 |

|

I should mention that I kept an eye on all potential rubbing surfaces.

That_silver_sti_22

> CleverUsername

That_silver_sti_22

> CleverUsername

08/31/2015 at 12:40 |

|

Meh, I can pull and replace the trans in my mustang by myself with just a floor jack in about at hour.

Now my Audi on the other hand... Lord help me if that thing ever needs to come out.

Hoy! Lip buddy pawnch!

> CleverUsername

Hoy! Lip buddy pawnch!

> CleverUsername

08/31/2015 at 12:42 |

|

For my projects, removing the engine, transmission (and in one case), transaxle from top is a study of madness. Even dropping them requires you to jack the car up at least 2 feet (clearance). A transmission jack is nice if you have a lift or for smaller, lighter things but a creeper or moving dolly is way easier.

For my projects

Clay_T

> NoahthePorscheGuy

Clay_T

> NoahthePorscheGuy

08/31/2015 at 12:55 |

|

Dad and I do it a couple times a year... We have a short gear box and a long box for Willow and Fontana.

(occasional swearing when we forget to disconnect the shifter linkage.)

rayJoyal

> crowmolly

rayJoyal

> crowmolly

08/31/2015 at 12:55 |

|

Yup. 2001 TA. Factory clutch doesnít like nitrous.

We didnít start with a tranny jack, the plan was to just muscle it back on. The T56 is heavy - like 125 pounds and you have to nail it just right or you canít slide it on. Even then I had to get longer bolts and suck it up one turn at a time praying I wouldnít crack the case.

I was so convinced I had something installed wrong so I took it apart and removed the slave cylinder and mocked it up. Nothing wrong, just a big spring on the slave that you have to compress to get it all buttoned up. And then the process of bleeding the hydraulics. I didnít know they made remote bleeder kits for the car. I now own a pressure bleeder because of that.

Ugh. I love my TA, but that job SUCKED. I could R&R the automatic from my dirt Camaro in about 2 hours with nothing but hand tools, a floor jack, a slurpee and my buddy.

But yes: a transmission jack is awesome for doing transmission installs because you can raise/lower/tilt in tiny increments instead of trying to force it on while transmission fluid pours down your forehead and your helper canít reach the bolts and itís getting heavy and could someone please get one of those f*cking bolts in please and dammit itís slipping and shit now we have to start over.

dustynnguyendood

> TheChafing

dustynnguyendood

> TheChafing

08/31/2015 at 12:56 |

|

It is becoming that way. The problem for most driveway swaps becomes how to safely raise the vehicle high enough in the air to allow the drivetrain components to be extricated from underneath.

Quade

> CleverUsername

Quade

> CleverUsername

08/31/2015 at 12:57 |

|

http://www.amazon.com/OTC-1521A-CapaÖ

I bought one of these. I do enough transmissions itís worth it.

Quade

> CleverUsername

Quade

> CleverUsername

08/31/2015 at 12:59 |

|

Yeah, I decide before the job of I need to pull everything. If Iím doing other things like timing belt and water pump at the same time, I often just pull them both as a unit.

CammedCTSV

> CleverUsername

CammedCTSV

> CleverUsername

08/31/2015 at 13:00 |

|

Here in the dirty south, if you canít flat-back your transmission onto the dowel pins, you face ridicule and shame from other males

Booger Davis

> Drakkon- Most Glorious and Upright Person of Genius

Booger Davis

> Drakkon- Most Glorious and Upright Person of Genius

08/31/2015 at 13:06 |

|

If they donít kill us first

Booger Davis

> CleverUsername

Booger Davis

> CleverUsername

08/31/2015 at 13:10 |

|

This http://www.harborfreight.com/450-lb-low-lifÖ

Iíve used it for other things - differential R&R, installing doors, right now itís in use holding a quarter panel in place so I can get it fitted and welded.

The Don

> CleverUsername

The Don

> CleverUsername

08/31/2015 at 13:12 |

|

And here I would just benchpress the transmission into place...

BadLag

> Achieve

BadLag

> Achieve

08/31/2015 at 13:18 |

|

I did this with a 65 Mustang 4 speed, on jack stands, pulled the tranny out onto my chest, kinda placed it on the ground then dragged it out from under the car.....Good Times!

I worked as a mechanic and did use tranny jacks so doing this in a friends garage as a favour better be worth something...Oh Yea, PIZZA and BEER!

SchwarzeEwigkt

> CleverUsername

SchwarzeEwigkt

> CleverUsername

08/31/2015 at 13:23 |

|

While I salute your backyard engineering and stand in awe of the size of your gonads, I feel like this is NOT. SAFE. AT. ALL. I mean, what do I know, but I can think of several ways to get dead doing that. Also, I bought a transmission jack ó think tiny mechanical manlift or gigantic scissor jack on casters with a v-shaped plate and a safety chain ó for the last clutch job I did. It was maybe $40. Sure, I use it infrequently, but I sure as hell would use it more than an engine hoist and it's a hell of a lot smaller. It's also designed for the job, stable and there's very little opportunity for it to go wrong.

BadLag

> rayJoyal

BadLag

> rayJoyal

08/31/2015 at 13:24 |

|

ďcould someone please get one of those f*cking bolts in pleaseĒ

Been there many times :)

SchwarzeEwigkt

> lawlence

SchwarzeEwigkt

> lawlence

08/31/2015 at 13:25 |

|

Would that there were any E30ís around here that still worked. And any space in my stable.

...maybe I can convince my wife to let me get one once my shitty Audi dies...

SchwarzeEwigkt

> McMike

SchwarzeEwigkt

> McMike

08/31/2015 at 13:26 |

|

ďMrs McMike pumped it while I laid underneath it, holding it with my knees...Ē

May I take you out of context?

SchwarzeEwigkt

> Cixelsyd

SchwarzeEwigkt

> Cixelsyd

08/31/2015 at 13:29 |

|

The person who got volunteered (voluntold?) to change the clutch while you guys held the bar; when he drives a motorcycle, he has a sidecar specifically for his balls, right?

SchwarzeEwigkt

> Urambo Tauro

SchwarzeEwigkt

> Urambo Tauro

08/31/2015 at 13:32 |

|

Wait. I have those exact ratchet straps. I got them at harbor freight. They're NOT up to that. I mean, holding a Christmas tree or some lumber on your roof? Sure. I secured a cargo box onto my roof for a road trip I'm on right this second. Worked great. But housing a transmission while you're under it? Just peed my pants a little.

CleverUsername

> SchwarzeEwigkt

CleverUsername

> SchwarzeEwigkt

08/31/2015 at 13:39 |

|

Fair perspective, but this solution allowed me to never be under the transmission, and the ratchet strap can hold something much heavier than 150 lbs. Aside from that, I find that most people can find a use for a floor jack and an engine hoist afterward, even if the hoist takes up a lot of space.

Opa Brummbaer

> CleverUsername

Opa Brummbaer

> CleverUsername

08/31/2015 at 13:49 |

|

Actually, in my younger days I just used my chest for both transmissions and VW aircooled engines. Not sure I could have handled an automatic from the current era. When I was a 25 year old Marine, I was a lot more buff than I am now as a 68 year old with, wait for it, back problems!

CleverUsername

> CammedCTSV

CleverUsername

> CammedCTSV

08/31/2015 at 13:51 |

|

Sounds like a sound system.

Diavel in Hawaii

> CleverUsername

Diavel in Hawaii

> CleverUsername

08/31/2015 at 13:51 |

|

The last transmission pull I did was on a 1975 Pinzgauer 6x6. Enough ground clearance to sit under the truck comfortably and the tranny weighed all of 60 lbs. Also, there is a hatch in the bed that allows access to the top of it. Vehicles designed to be worked on FTW.